Definitions and Capabilities:

CAN – Controller Area Network up to 1M bits/sec

LIN – Local Interconnect Network. This is programmed to simulate the shifter lever on Freightliners with an automated transmission.

PWM – Pulse Width Modulated with adjustable frequency and duty cycle. These are 0 to 5V square wave signals.

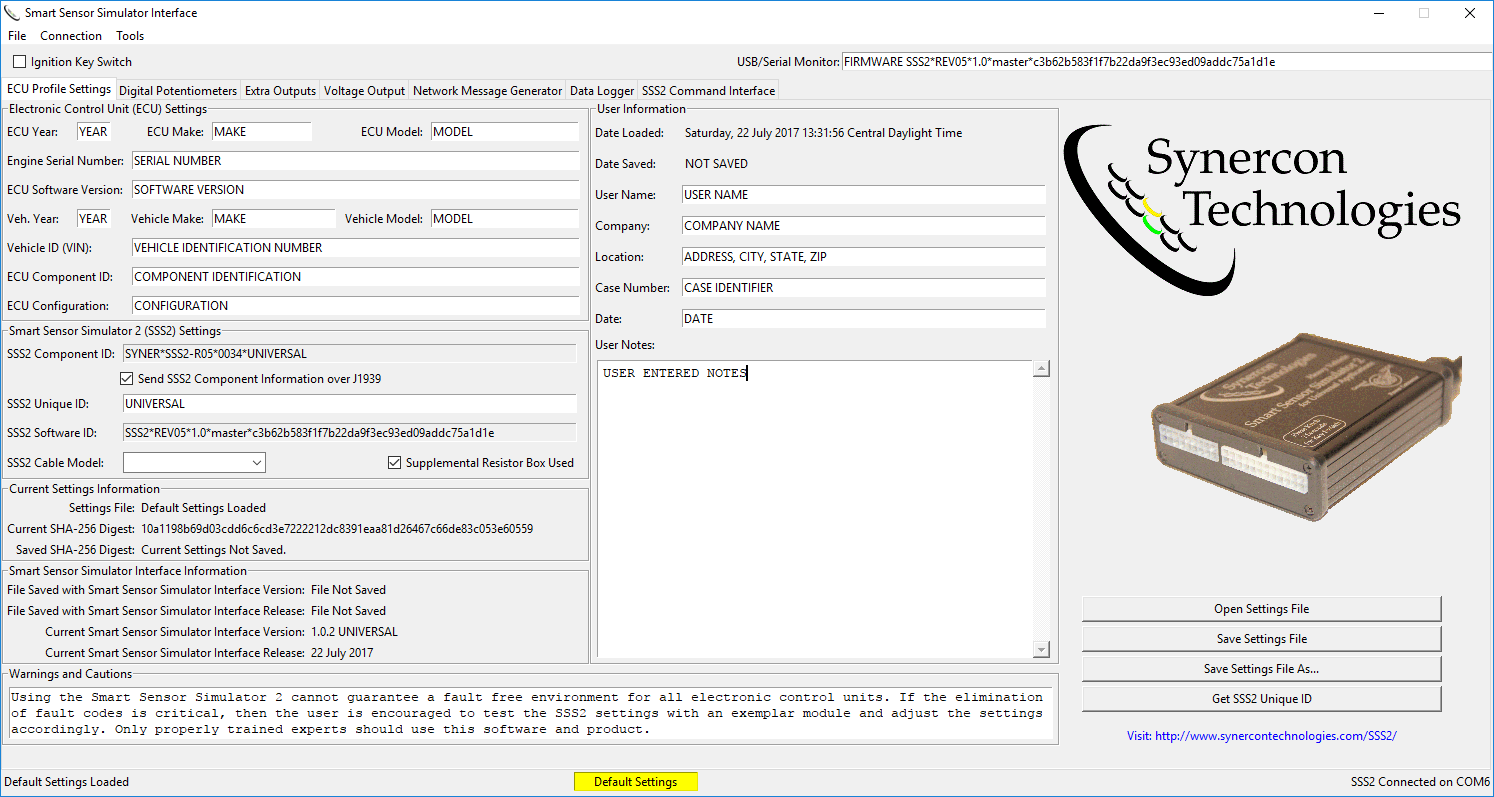

Digital Potentiometers

The digital potentiometers are 12V tolerant devices with independent terminal connection control. A potentiometer has three terminals: Terminal A, the Wiper, and Terminal B connected to ground. The potentiometer is rated to have a resistance from Terminal A to Terminal B. The wiper picks off from along the resistor string. The terminals can be configured to open and close independently. This gives you the ability to connect the potentiometer as a voltage divider, resistance to ground, or resistance to a high source. The terminals are connected by selecting the checkboxes on the SSS Interface under the Digital Potentiometers tab.

Digital potentiometers can simulate signals that are used for

- Temperature Sensors

- Pressure Sensors

- Analog Accelerator Pedals

- Actuator Presence (i.e. the presence of an actuator)

The digital potentiometers used in the SSS2 are the MCP41HV51 and MCP45HV51. The digital potentiometers have a limit such that the wiper plus the terminal is between 250 to 300 ohms.

Analog Output

Analog outputs generate signals from 0 to 5 V. The signal is generated by a Digital to Analog Converter (TI DAC7678) and buffered with an op-amp. Each signal is capable of sourcing 25 mA.

Analog Outputs can simulate signals for:

- Pressure Sensors

- Switches to ground (by setting the output voltage to 0)

Analog outputs are similar to a voltage divider when examining the signal with a meter. However, voltage dividers based on a potentiometer sink current and analog outputs can both sink and source current.

Pulse Width Modulated Output

Pulse width modulated outputs are square waves from zero to +5V that have an adjustable frequency and duty cycle. These signals can be used to simulate analog values by adjusting the duty cycle. In other words, a voltmeter will read between 0 and 5v based on the duty cycle. A duty cycle of 0 means the output is driven to ground through an op-amp. A 100% duty cycle means the signal is always on at +5v. The frequency can be set from 0 to 5000 Hz.

Pulse width modulated signals are the only way to simulate throttle position sensors for some ECUs, like Caterpillar and PACCAR MX.

These signals can also be used to generate speed signals for researching event data recorder capabilities.

Not all channels have independent frequency settings. The PWM1 and PWM2 signals have a common frequency that can only go as low as 245 Hz. PWM3 and PWM4 share the same frequency. PWM5 and PWM6 share the same frequency. The output of PWM 3 shares the pinout for a swithed +12V supply and has a 10uF capacitor to ground. This capacitor acts like a low-pass filter, so high frequency values on PWM3 tend to be averaged out and do not show the switching behavior of the other PWM signals.